Ladders and Scaffold rental

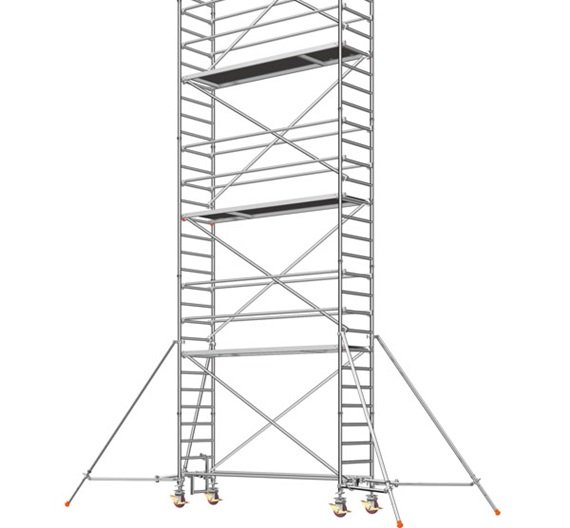

Rolling scaffolding is best for all types of construction work. Suitable both indoors and outdoors. Robust wheels for good maneuverability and even positioning when you work. A variety of wheel coverings means that they can also be used on delicate floor surfaces.

Various modifications rise.

MORE SECURITY ON THE CONSTRUCTION SITE

To comply with European safety laws and requirements, the Layher product portfolio includes Safety Structure P2. Security structure P2 provides collective protection.

If you already have a Layher roller tower, you can easily convert this to the P2 variant.

LADDER FRAMES

The ladder frame is part of the framework and also functions as a ladder. The ribs on the steps ensure a high level of slip and grip safety in a vertical ladder.

The ladder frames are available in lengths of 1.00 m and 2.00 m and in widths of 0.75 m and 1.50 m.

Long, tapered tube connectors ensure a secure and even plug connection from one ladder frame to the next, and can be easily secured using a spring-loaded locking cotter pin.

WHEELS

Robust wheels for good maneuverability and safe positioning when working. A variety of wheel coverings means that they can also be used on delicate floor surfaces. The steel spindles enable very simple and precise height adjustments and distribute the load centrally on the locked wheel. Stability is increased as a result, allowing the user to work efficiently.

SOLOTOWER - FOR QUICK, SIMPLE AND SAFE ASSEMBLY BY ONE PERSON

SoloTower from Layher is a small rolling tower that can be assembled quickly, safely and easily by a single person, up to a working height of 6.15 metres.

Economical, efficient and ergonomic logistics for storage, transport and handling on site, due to compact dimensions of all components.

More safety when moving up to the next platform, due to double railings that are pre-assembled using the 3-T method.

Safer assembly and disassembly done by just one person because you can send the compact components from level to level using the SoloTower mounting hook.

Tool-free, quick and easy assembly due to the proven Layher connection technology in the snap-on claw.

Aluminum end and side skirting boards which are pre-assembled to create a collapsible skirting board that ensures quick installation on the platform.

Designed according to European standard DIN EN 1004 for mobile work platforms, for maximum quality and safety.

– Uni Standard P2 and Uni Wide P2 rolling towers are also available with tower supports.

– They are supplied complete as a set in a wide range of mounting heights up to a working height of 13.2 m.

– The use of Layher tower supports means that the mobile beam is no longer necessary and the total weight of the tower is reduced by up to 43 kg. In addition, there is a need for fewer ballast weights.

BRACKET FOR PLATFORM SURFACE - EXTENSION OF THE WORKING AREA FOR UNI STANDARD AND UNI WIDE

– Special designs are individualized tower structures that make work safer and faster on many construction sites.

– Retrofitting the complete rolling tower is possible.

– Quick and easy extension of the work surface by up to 1.5 m.

– Permissible actual load: 1.5 kN/m² (scaffolding group 2).

ALUMINUM LADDER

Layher aluminum ladders provide strength and durability at low weight and are used in all industries, as a work tool for light work or to provide access to high places. Non-slip ladder feet, grooved steps and low weight ensure safety and ergonomic working conditions.

THE QUALITY CAN BE SEEN IN THE DETAILS

1. Ladders and steps are made of strong, sealed extruded profiles without longitudinal welding seams and are very robust. They are pressed into the cages at 4 points. The shape of the triangular steps secures them against rotation, and the press assembly ensures a high degree of lateral stability for the ladder. The strong grooves on the steps and rails ensure a very good foothold.

2. Plastic-shielded steel hinges with wobble-free screw fittings that are secured against loosening, for long life.

3. The special construction of the wooden ladder profile means that it can handle high loads even with a low weight on the ladder. Balls along the outer flange prevent damage to the step flange, e.g. when you push it over loading racks.

4. The shape of the step’s pressed connection point increases the step’s contact surface with the inner wooden wall, so that greater mechanical loads can be transferred.

5. Additional stiffeners at the ends of the brackets ensure that the values according to DIN EN 131 are more than met.

6. Tear-proof polyester straps to transfer loads up to 3 kN.

7. Non-slip ladder feet with special support surfaces ensure non-slip positioning. They also allow easy retrofitting of cross braces.